Description:

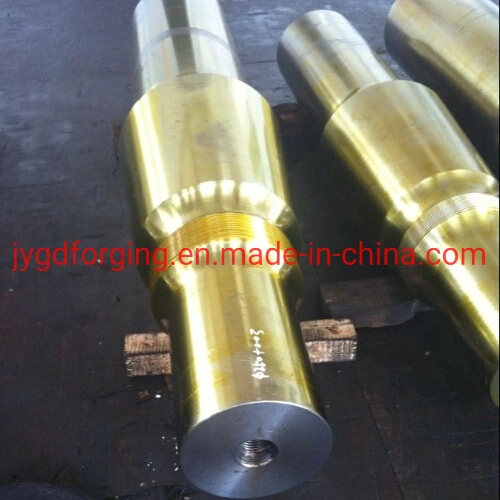

The heavy forging: forged ring, shaft, roller, flange, or gear is widely used for various industries For example: Metallurgy, mining, power station and so on. The manufacturing equipment is 185MN or 100MN hydraulic press, the forging ratio >4.5, the technical condition is in accordance with the standard of ASTM, EN, DIN, ASME or GB etc.

The product can be provided as per your drawing or specified requirements.

Smelting Process:EF+LF + VD+VC The process as follow :Ingot →heat → forging → Heat treatment (Normalizing+ tempering) → Inspection →rough machining→UT →2th Heat treatment →finishing machining →Inspection

Applications: The heavy forging: forged ring, shaft, roller, flange, or gear is widely used for various industries For example: Metallurgy, mining, power station and so on.

Specifications:

| Description | The heavy forging: forged ring, shaft, roller, flange, or gear |

| material | Alloy steel or stainless steel |

| Material standard | ASTM or GB/T3077-1999 |

| Specification | As per specified requirements |

| Weight | Max. 250 ton |

| Smelting Process: | EF+LF + VD+VC |

| Process | Ingot→heat → forging → Heat treatment (Normalizing+ tempering) → Inspection →rough machining→UT →2nd Heat treatment →finishing machining →Inspection |

| UT standard | EN10228, ASTM A388 or JB/T 5000.15-1998 |

Competitive Advantage:

The heavy forging is manufactured by large scale stated enterprise. Advanced technical process from smelting steel to forging and heat treat guarantees the product quality. Closed relationship with several famous stated enterprises guarantee "in-time delivery" and competitive price.

Excellent product quality and service, competitive price, "in-time" delivery.

| Item | Process | Facility | Inspection items | Standard |

01 | Steel material inspection | Chemical composition (EF+LF+VD) | Material standard | |

| surface | Ingot inspection specification | |||

| Ingot type and weight | Material standard | |||

| 02 | Material store | Division put | warehouse management | |

| 1 | Heat | Heat furnace | Temperature/Time | Heating process specification Forging production procedure |

| 2 ↓ | Forging | Press | Reduction ratio,forging temperature,deformation, Surface and dimensions | Forging process card Forging procedure |

| 3 ↓ | Heat treatment | heat treatment furnace | heat treatment charts | 1st heat-treatment card Forging procedure |

| 4 ↓ | Rough inspection | Dimensions, apperance, Mark | Inspection specification Forging procedure | |

| 5 ↓ | Rough UT | UT equipment | Single defect, concentrated Defects bottom wave attenuation | UT standard or customer's technical requirements |

| 6 ↓ | Saw cutting | Saw machine | Dimension | IQC and forging |

| 7 ↓ | rough turning | turning-lathe | Dimension,appearance | Rough machining drawing |

| 8 ↓ | UT | UT equipment | Single defect, concentrated defects bottom wave attenuation | UT standard or customer's technical requirements |

| 9 ↓ | Q+T heat treatment | heat treatment furnace | heat treatment charts | Heating process specification |

| 10 ↓ | Sampling or machining | machining tool | rough machining drawing sampling drawing | sample machining drawing |

| 11 ↓ | mechanical property test | tensile testing machine/ impact testing machine | ambient temperature,humidity, Test temp.Sample dimension, test method | Standard technical specification |

| 12 ↓ | finish machining | machining tool | Dimension,appearance | finish machining drawing |

| 13 ↓ | UT | UT equipment | Single defect, concentrated Defects bottom wave attenuation | UT standard or customer's technical requirements |

| 14 ↓ | MT | MT equipment | Magnetic particle indication | Test standard or Technical requirements |

| 15 ↓ | Mark | Steel seal | marking content | Product standard Technical requirements Forging process |

| 16 ↓ | Final inspection | Appearance, dimension, mark acceptance inspection | Product inspection specification Product standard P.O. | |

| 17 | Protection/ package | Blasting Blasting equipment | appearance coating thickness | Product standard Technical requirements |

How to pack