garbage can Mould/Die Casting Mold/China Moulds/Plastic ash-bin Products Moulds/Injection Moluld

Longxiang Introduction

Longxiang Group Limited was established in Guangzhou city in 1998. After over 15 years of hard work, Longxiang has grown to be one of the highest reputable mould maker in China with 120 employees' 5000 sq. Meter working shop.

Up to now, Longxiang has exported about 2400 sets of moulds to 38 countries. The moulds we made include automotiveparts (dashboards, inner decorating accessories, etc.), electrical appliances (washing machine, air conditioner,refrigerator, television, etc.), IT industry products (cell phones, computer, etc.), householder products(micro-wave oven, juicer, etc.), office accessories (telephone, printer, etc.) as well as other various of products.

We look forward to participating at the success of your next project.

Working shop

Mold Specification

| Mold Material | 45#,P20 steel, 718, 2738, H13, NAK80, 2344, 2343, S136, etc . |

| Mold Type | Plastic Injection Molding |

| Product Material | ABS,PA,PA66+GF,POM,PC,PP,PET,TPE,PVC,HDPE,etc |

| Mold Standard | HASCO, DME, MISUMI, JIS, LKM, etc. |

| Mold Tooling Equipment | Lathe,Milling,Grinder,Drill,CNC,EDM, Wire cut machine,Punch machine |

| Injection Mold Machine | 80T to 2800T |

| Product Weight | 50-20000g |

| GateType | Side Gate, Sub Gate, Direct Gate, Hook Gate, Pin Point Gate, etc. |

| Runner Type | Cold Runner or Hot Runner |

| Cavity | Single or Multi cavities |

| Treatment | Heat treatment and Nitriding,polish ect. |

| Mold Life | 45#:50,000 to 100,000 shots |

| P20:100,000 to 200,000 shots | |

| 718: 200,000 to 300,000 shots | |

| H13: 300,000 to 500,000 shots | |

| Lead Time | Generally mold making will take around 30 days 7-10 day to mass production |

| Package | Wooden packing box for molds inner packed in opp bags, outside packed in standard export carton |

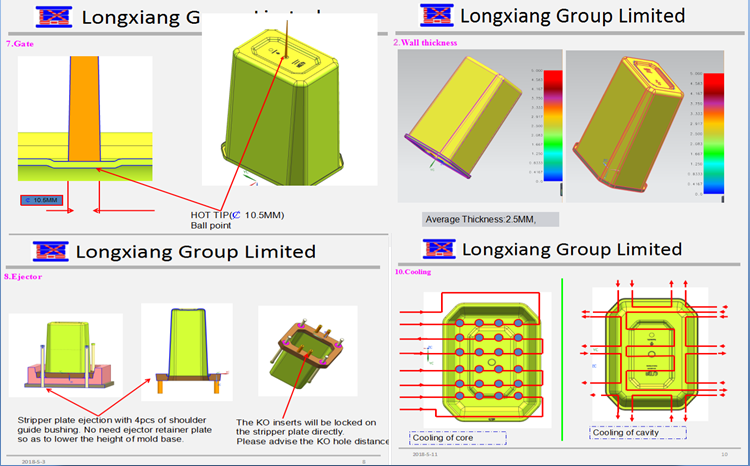

We have rich experience to make garbage bin mold, with100% make sure solve the core offset and uneven wall thickness problem.

Material Specification

| Material type | Abbr | Description and typical applications |

| Acrylonitrile Butadiene Styrene | ABS | Opaque & tough / Phones & computers |

| Polypropylene | PP | Opaque & tough / Beer crates |

| Polystyrene | PS | Clear & Brittle / Toys & model kits |

| Polystyrene High Impact | HIPS | Opaque & tough / Toys & model kits |

| Acetyl | POM | Natural & very tough / Gears & bearings |

| Polycarbonate | PC | Clear and very tough / Street lamp covers & safety helmets |

| Plasticized Polyvinylchloride | PVC | Opaque & flexible / Shoe soles & electrical insulation |

| Polyamide 6 | PA6 | Opaque & very tough / Bushes, bearings & curtain fittings |

| Polyamide 6.6 | PA6.6 | Opaque, tough and rigid / Housings & handles |

| Polyamide 12 | PA12 | Opaque tough & rigid / Air filters & spectacle frames |

| Polyethylene low density | LDPE | Waxy tough & flexible / Kitchenware & sealing lids |

| Polyethylene high density | HDPE | Waxy tough & stiff / Crates & chair seats |

| Thermoplastic Elastomer | TPE | Flexible & tough / Seals & washers |

| Thermoplastic Rubber | TPR | Flexible & tough / Seals & washers |

| Acrylic | PMMA | Transparent & Brittle / Lenses & car lights &Display |

| Polystyrene General Purpose | GPPS | Clear & brittle / Ball point pen barrels |

| Polyphenylene Sulphide | PPS | Brown & very strong / Guides & bearings |

| Polyphenylene Oxide | PPO | Tough & stable / Electrical parts |

| Rigid Polyvinyl Chloride | UPVC | Opaque & tough / Fascia fittings & guttering |

| Styrene Acrylonitrile | SAN / AS | Clear & brittle / Table & picnic ware |

| Polyether Sulphone | PES | Clear & tough / Metal replacement parts |

| Cellulose Acetate | CA | Clear & tough / Spectacle frames |