Specification:

| 1.Material | Aluminum, Brass, Bronze, Copper, Hardened Metals , steel,nylon ect |

| 2.Tolerance | +/-0.05mm |

| 3.Finishing | tooth hardended,black oxidation,zinc plated ect. |

| 4.Edges and holes | debarred |

| 5.Surfaces | free of scratches |

| 6.Material capabilities | aluminum, stainless steel, copper, plastic and more |

| 7.Various materials and finishing ways are available | |

| 8.Non-standard aluminum product | |

| 9.Material and finishing comply with RoHS Directive | |

| 10.Small orders are welcome | |

Technical Details

Technical Process | CNC machining, EDM W/C |

Dimension | Client's artwork is available |

Capability | Milling:Length,machining range up to 1100*600 mm |

Turning: Diameter 0.05mm~300mm ; Length 0.5mm ~ 750mm | |

Wire Cutting: machining range can up to 450*400*300mm | |

Precision | Turning and Milling:+/- 0.002mm(+/-0.000098 inch) |

Wire Cutting: +/- 0.002 mm (+/-0.000098 inch) |

Why Choose us:

1. Fully Machining Services:

Gringing parts , Machining parts, CNC milling and turning parts , CNC milling parts, CNC

metal parts, grinding parts, stamping parts, casting and forging parts, assembly service.

2.Various Machining Materials:

Metal parts, stainless steel parts, alloy steel parts ,brass parts, bronze parts, copper

parts, aluminum parts, plastic parts, ect.

3.Various Finishes:

Anodizing, Electroplating, Polishing, Powder Coating, Blacken, Hardening, Painting and

many other treatment of the parts.

4.Quality Assurance :

IPQC inspect each precision grinding parts during every processing step; 100% inspection before shipment by micrometer, height gauge, projector measuring machine, coordinate

measuring machine(CMM), ect. Any disqualification will be responsible by us.

5.Advantage:

1>.Non-standard/standard/OEM/ODM/customized service provided

2> No MOQ, no quantity limited

3 >Fast lead time

4> Can meet DIN,JIS,ASTM,AISI,BS,GB standard

Related Products

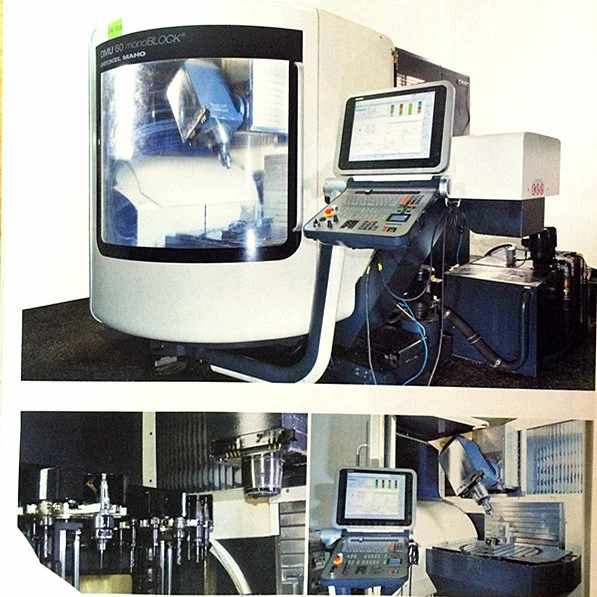

Equipment Show

After Service

Welcome consult with us, we service:

1. Best Solution for your production

2. Fast delivery for your urgent order.

3.sandy + 86 18680402057