6060 T4/T5/T6 Aluminum Alloys Extruded Profiles for Structural Material of Railway Vehicle

Custom Industrial

Chalco Aluminum produces industrial profiles upon demand of the client and offers solutions in many fields such as Transport, Engineering, Automobile Industry and Electrical Applications etc.

A dedicated production unit, which is used for that purpose, guarantees high quality products:

A dedicated production unit, which is used for that purpose, guarantees high quality products:

- Precision in size

- High quality coatings

- Smooth, polished and flat surfaces

- Mechanical Processing of aluminium profiles

- Anodization and Special Cutting

- Special Packages

- According to ISO Standards

Application:

| Aerospace & Aircraft | Hard alloy extruded shapes, hard alloy drawn seamless tube, hard alloy cold finished rod& bar |

| Home furnishing | Furniture, Garden furniture, Shutters , Lighting, Self Brackets, Guides of curtains |

| Energy | Photovoltaic panels and individual constructions Heaters, heating Air vents for air conditioning systems |

| Vehicles | Automotive Industry Bodywork |

| Electrical devices | Home Appliances Brush bodies |

| Professional equipment | Commercial refrigerators Medical Equipment measuring Tools |

| Advertising material | Advertising signs Stand |

| Advertising signs Stand | Bikes |

Aluminum alloys extruded profiles used for structural material of railway vehicle carbodies

The railway cars are typically designed for a 30 year life. Thus, the rail industry is very cautious when it select the alloys. Trade offs between cost and performance dictate the materials

used in construction of passenger vehicles. Although aluminum alloys are more expensive than steel they are selected for there low density.

At present the Al-Mg-Si 6XXX alloys (e.g. 6061,6106,6082,6005,6005A,6008,6060,6063,6A01) and Al-Mg 5XXX alloys (e.g. 5083,5052,5754)and Al-Zn-Mg-Cu 7XXX series (e.g. 7005,7020,7B05)

are used to fabricate structural material of railway vehicle carbodies.

Chalco Aluminum has Aluminum alloys extruded profiles used for structural material of railway vehicle carbodies,has different alloys 6061,6106,6082,6005,6005A,6008,6060,6063,6A01, 5083,5052,5754, 7005,7020,7B05,etc with different supplied temper H112,T1,T4,T5,T6,etc.

1)Alloy,Temper and Profile category of Aluminum alloys extruded profiles used for structural material of railway vehicle carbodies

2)The chemical component of Aluminum alloys extruded profiles used for structural material of railway vehicle carbodies

3-1)Allowable curved surface gap (unit:mm)

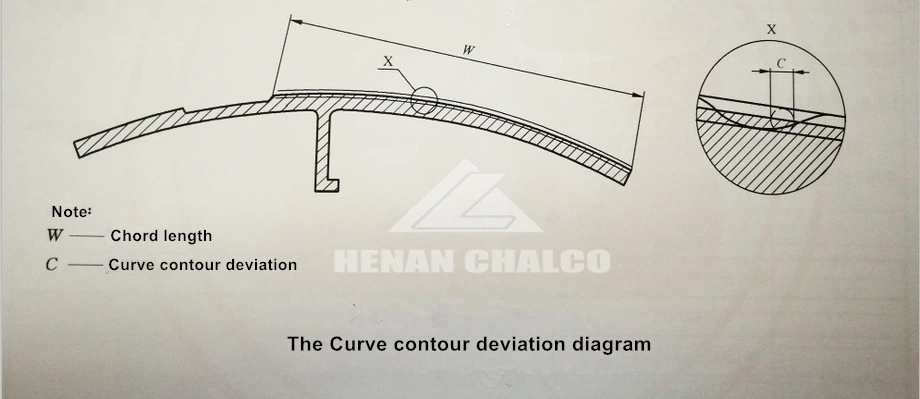

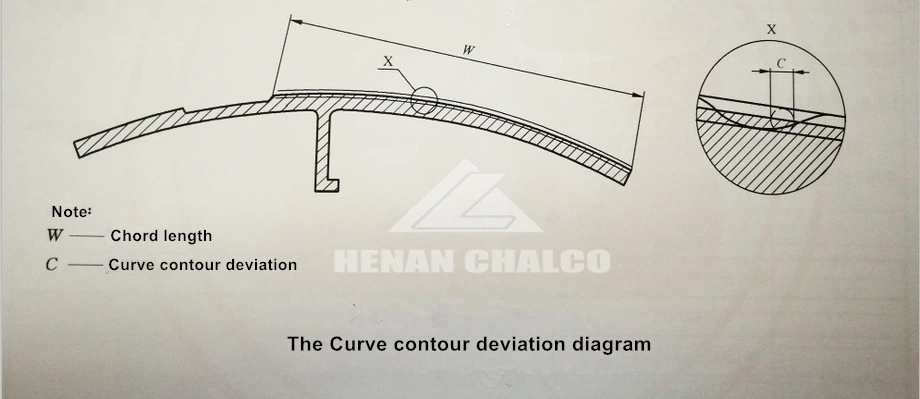

3-2)Curve contour deviation(unit:mm)

3-3)Allowable Cutting slant angle

4)Mechanical Property of Aluminum alloys extruded profiles used for structural material of railway vehicle carbodies

5)Tensile mechanical properties of welded joints at room temperature

6)The bending radius of the profile

The railway cars are typically designed for a 30 year life. Thus, the rail industry is very cautious when it select the alloys. Trade offs between cost and performance dictate the materials

used in construction of passenger vehicles. Although aluminum alloys are more expensive than steel they are selected for there low density.

At present the Al-Mg-Si 6XXX alloys (e.g. 6061,6106,6082,6005,6005A,6008,6060,6063,6A01) and Al-Mg 5XXX alloys (e.g. 5083,5052,5754)and Al-Zn-Mg-Cu 7XXX series (e.g. 7005,7020,7B05)

are used to fabricate structural material of railway vehicle carbodies.

Chalco Aluminum has Aluminum alloys extruded profiles used for structural material of railway vehicle carbodies,has different alloys 6061,6106,6082,6005,6005A,6008,6060,6063,6A01, 5083,5052,5754, 7005,7020,7B05,etc with different supplied temper H112,T1,T4,T5,T6,etc.

1)Alloy,Temper and Profile category of Aluminum alloys extruded profiles used for structural material of railway vehicle carbodies

| Alloy | Temper | Profile category |

| 5052,5754 | H112 | 1 |

| 5083 | H112 | 2 |

| 6005 ,6005A,6008 | T4,T6 | 1 |

| 6060 | T4,T5,T6 | 1 |

| 6063 | T1,T4,T5,T6 | 1 |

| 6101,6061,6082 | T6 | 1 |

| 6A01 | T4,T5 | 1 |

| 7003 | T5 | 2 |

| 7005,7020 | T6 | 2 |

| 7B05 | T4,T5,T6 | 2 |

2)The chemical component of Aluminum alloys extruded profiles used for structural material of railway vehicle carbodies

| Alloy | Chemical component(%) | ||||||||||||

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Zr | Other | Al | |||

| Each | Total | ||||||||||||

| 5052 | ≤0.25 | ≤0.40 | ≤0.10 | ≤0.10 | 2.2- 2.8 | 0.15-0.35 | ≤0.10 | - | - | - | ≤0.05 | ≤0.15 | Remain |

| 5754 | ≤0.40 | ≤0.40 | ≤0.10 | ≤0.50 | 2.6- 3.6 | ≤0.30 | ≤0.20 | Mn+Cr:0.10-0.60 | ≤0.15 | - | ≤0.05 | ≤0.15 | Remain |

| 5083 | ≤0.40 | ≤0.40 | ≤0.10 | 0.40-1.0 | 4.0-4.9 | 0.05-0.25 | ≤0.25 | - | ≤0.15 | - | ≤0.05 | ≤0.15 | Remain |

| 6008 | 0.5-0.9 | ≤0.35 | ≤0.30 | ≤0.30 | 0.40-0.7 | ≤0.30 | ≤0.20 | V: 0.05-0.20 | ≤0.10 | - | ≤0.05 | ≤0.15 | Remain |

| 6005 | 0.6-0.9 | ≤0.35 | ≤0.10 | ≤0.10 | 0.40-0.6 | ≤0.10 | ≤0.10 | - | - | ≤0.10 | ≤0.05 | ≤0.15 | Remain |

| 6005A | 0.5-0.9 | ≤0.35 | ≤0.30 | ≤0.50 | 0.40-0.7 | ≤0.30 | ≤0.20 | Mn+Cr:0.12-0.50 | ≤0.10 | - | ≤0.05 | ≤0.15 | Remain |

| 6061 | 0.40-0.8 | ≤0.7 | 0.15-0.40 | ≤0.15 | 0.8-1.2 | 0.04-0.35 | ≤0.25 | - | ≤0.15 | - | ≤0.05 | ≤0.15 | Remain |

| 6082 | 0.7- 1.3 | ≤0.50 | ≤0.10 | 0.40-1.0 | 0.6-1.2 | ≤0.25 | ≤0.20 | - | ≤0.10 | - | ≤0.05 | ≤0.15 | Remain |

| 6063 | 0.20-0.6 | ≤0.35 | ≤0.10 | ≤0.10 | 0.45-0.9 | ≤0.10 | ≤0.10 | ≤0.10 | - | ≤0.05 | ≤0.15 | Remain | |

| 6060 | 0.30-0.6 | 0.10-0.30 | ≤0.10 | ≤0.10 | 0.35-0.6 | ≤0.05 | ≤0.15 | - | ≤0.10 | - | ≤0.05 | ≤0.15 | Remain |

| 6101 | 0.30-0.7 | ≤0.50 | ≤0.10 | ≤0.03 | 0.35-0.8 | ≤0.03 | ≤0.10 | B:0.06 | - | - | ≤0.03 | ≤0.10 | Remain |

| 7003 | ≤0.30 | ≤0.35 | ≤0.20 | ≤0.30 | 0.5-1.0 | ≤0.20 | 5.0-6.5 | - | ≤0.20 | 0.05-0.25 | ≤0.05 | ≤0.15 | Remain |

| 7005 | ≤0.35 | ≤0.40 | ≤0.10 | 0.20-0.7 | 1.0-1.8 | 0.06-0.20 | 4.0-5.0 | - | 0.01-0.06 | 0.08-0.20 | ≤0.05 | ≤0.15 | Remain |

| 7020 | ≤0.35 | ≤0.40 | ≤0.20 | 0.05-0.50 | 1.0-1.4 | 0.10-0.35 | 4.0-5.0 | Zr+Ti 0.08-0.25 | - | 0.08-0.20 | ≤0.05 | ≤0.15 | Remain |

3-1)Allowable curved surface gap (unit:mm)

| Curved surface chord length | Allowable curved surface gap on below chord length | |

| Any 25mm chord length | All the chord length( W) | |

| ≤25 | --- | ≤0.13 |

| >25 | ≤0.13 | ≤0.6% X W |

3-2)Curve contour deviation(unit:mm)

| Circumscribed circle diameter | Curve contour deviation C |

| ≤30 | ≤0.30 |

| >30-60 | ≤0.50 |

| >60-90 | ≤ 0.70 |

| >90-120 | ≤1.0 |

| >120-150 | ≤1.2 |

| >150-200 | ≤1.5 |

| >200-250 | ≤2.0 |

| >250-300 | ≤2.5 |

| >300-400 | ≤3.0 |

| >400-500 | ≤3.5 |

| >500-1000 | ≤4.0 |

3-3)Allowable Cutting slant angle

| Max width of Aluminium profile mm | Cutting slant angle |

| ≤ 150.00 | ≤ 3° |

| > 150.00-400.00 | ≤ 2° |

| >400.00 | ≤ 1° |

4)Mechanical Property of Aluminum alloys extruded profiles used for structural material of railway vehicle carbodies

| Alloy | Temper | Aluminum profile mode | Wall thickness (mm) | Cross sectional area cm² | Mechanical Property | BH(Brinell Hardness) HBW | ||||

| Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | ||||||||

| A | A50mm | |||||||||

| Not less than | ||||||||||

| 5052 | H112 | - | - | - | 170 | 70 | 15 | 13 | 47 | |

| 5754 | H112 | - | ≤25.00 | - | 180 | 80 | 14 | 12 | 47 | |

| 5083 | H112 | - | - | - | 270 | 140 | 12 | 10 | 70 | |

| 6005 6005A | T4 | solid | ≤25.00 | - | 180 | 90 | 15 | 13 | 50 | |

| hollow | ≤10.00 | - | 180 | 90 | 15 | 13 | 50 | |||

| T6 | solid | ≤5.00 | - | 270 | 225 | - | 6 | 90 | ||

| >5.00-10.00 | - | 260 | 215 | - | 6 | 85 | ||||

| >10.00-50.00 | - | 250 | 200 | 8 | 6 | 85 | ||||

| hollow | ≤5.00 | - | 255 | 215 | - | 6 | 85 | |||

| >5.00-15.00 | - | 250 | 200 | 8 | 6 | 85 | ||||

| >15.00-25.00 | - | 250 | 200 | 8 | - | - | ||||

| 6008 | T4 | solid | ≤10.00 | - | 180 | 90 | 15 | 13 | 50 | |

| hollow | ≤10.00 | - | 180 | 90 | 15 | 13 | 50 | |||

| T6 | solid | ≤5.00 | - | 270 | 225 | 8 | 6 | 90 | ||

| >5.00-10.00 | - | 260 | 215 | 8 | 6 | 85 | ||||

| hollow | ≤5.00 | - | 255 | 215 | 8 | 6 | 85 | |||

| >5.00-10.00 | - | 250 | 200 | 8 | 6 | 85 | ||||

| 6060 | T4 | - | ≤25.00 | - | 120 | 60 | 16 | 14 | 50 | |

| T5 | - | ≤5.00 | - | 160 | 120 | - | 6 | 60 | ||

| >5.00-25.00 | - | 140 | 100 | 8 | 6 | 60 | ||||

| T6 | - | ≤3.00 | - | 190 | 150 | - | 6 | 70 | ||

| >3.00-25.00 | - | 170 | 140 | 8 | 6 | 70 | ||||

| 6061 | T6 | - | ≤5.00 | - | 260 | 240 | - | 7 | 95 | |

| >5.00-25.00 | - | 260 | 240 | 10 | 8 | 95 | ||||

| 6063 | T1 | - | ≤12.00 | - | 120 | 60 | - | 12 | - | |

| >12.00-25.00 | - | 110 | 55 | - | 12 | - | ||||

| T4 | - | ≤25.00 | - | 130 | 65 | 14 | 12 | 50 | ||

| T5 | - | ≤3.00 | - | 175 | 130 | - | 6 | 65 | ||

| >3.00-25.00 | - | 160 | 110 | 7 | 5 | 65 | ||||

| T6 | - | ≤10.00 | - | 215 | 170 | - | 6 | 75 | ||

| >10.00-25.00 | - | 195 | 160 | 8 | 6 | 75 | ||||

| 6082 | T6 | - | ≤5.00 | - | 290 | 250 | - | 6 | 95 | |

| >5.00-50.00 | - | 310 | 260 | 10 | 8 | 95 | ||||

| 6106 | T6 | - | ≤10.00 | - | 250 | 200 | 8 | 6 | 85 | |

| 6A01 | T4 | solid | ≤25.00 | - | 160 | 70 | 15 | 13 | - | |

| hollow | ≤10.00 | - | 160 | 70 | 15 | 13 | - | |||

| T5 | - | ≤6.00 | - | 245 | 205 | - | 8 | - | ||

| >6.00-12.00 | - | 225 | 175 | - | 8 | - | ||||

| 7003 | T5 | - | ≤25.00 | - | 310 | 260 | 10 | 8 | - | |

| 7005 | T6 | - | ≤40.00 | - | 350 | 290 | 10 | 8 | 110 | |

| 7020 | T6 | - | ≤40.00 | - | 350 | 290 | 10 | 8 | 110 | |

| 7B05 | T4 | - | - | ≤200cm² | 315 | 195 | - | 11 | - | |

| T5 | - | - | ≤200cm² | 325 | 245 | - | 10 | - | ||

| T6 | - | - | ≤200cm² | 335 | 275 | - | 10 | - | ||

5)Tensile mechanical properties of welded joints at room temperature

| Alloy | Temper | Wall Thickness (mm) | Tensile mechanical properties Result at room temperature | |

| Tensile Strength (MPa) | Yield Strength (MPa) | |||

| Not less than | ||||

| 5083 | H112 | ≤ 15.00 | 270 | 125 |

| > 15.00 | 270 | 125 | ||

| 5754 | H112 | ≤ 15.00 | 180 | 80 |

| 6005 | T6 | ≤ 15.00 | 160 | 90 |

| 6005A | T6 | ≤ 15.00 | 165 | 115 |

| 6008 | T6 | ≤ 15.00 | 165 | 115 |

| 6061 | T6 | ≤ 15.00 | 175 | 115 |

| > 15.00 | 165 | 115 | ||

| 6063 | T6 | ≤ 15.00 | 110 | 65 |

| > 15.00 | 85 | 55 | ||

| 6082 | T6 | ≤ 15.00 | 185 | 125 |

| > 15.00 | 165 | 115 | ||

| 6106 | T6 | ≤ 15.00 | 160 | 95 |

6)The bending radius of the profile

| The profile Type | Wall thickness(mm) | The bending radius(mm) |

| Hollow Profile | ≤ 10 | 4 times of wall thickness |

| > 10 | 5 times of wall thickness | |

| Solid profile | ≤ 5 | 3 times of wall thickness |

| > 5-10 | 4 times of wall thickness | |

| > 10 | 5 times of wall thickness |